From “The Clayworking Plants of St. Louis” in the journal Brick, special issue on St. Louis, May, 1904, p. 227-228.

From “The Clayworking Plants of St. Louis” in the journal Brick, special issue on St. Louis, May, 1904, p. 227-228.

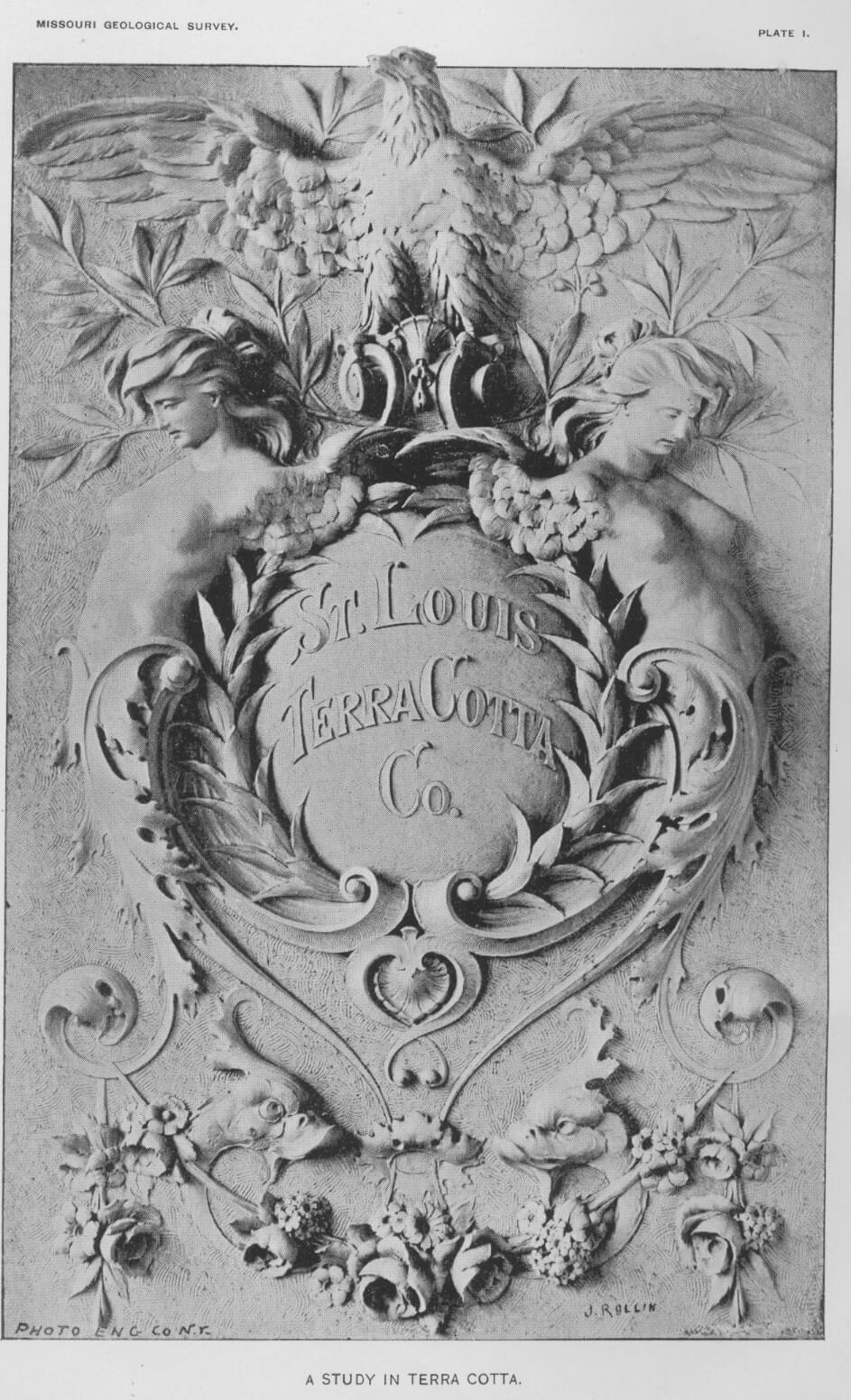

The works and main office of the St. Louis Terra Cotta Co. are at 5801-5815 Manchester Ave., but the company also has a downtown office at 720 Lincoln Trust Building. The plant was operated first in 1894, but only ran for 12 months, remaining idle until its acquisition by the present owners. The president of the company is D. N. Burruss; the vice-president and manager is R. F. Grady; the secretary, E. E. Wall, and the treasurer, H. D. Grady. The company’s works cover about one acre of land, the processes of manufacture being conducted in four buildings. Two buildings are 50 x 100 ft., three stories in height, and one building 125 x 40 ft., and one, two, three and four stories in height. This last building contains the plaster and modeling, clay grinding and enameling departments. Power for the various machines is furnished by a 100-h. p. Atlas engine and two boilers of 80 h. p. each, carrying 80 lb. pressure.

A number of clays are used in the manufacture of this terra cotta, among which may be mentioned Cheltenham shale, Tennessee ball clay, Georgia and Indiana clays, and flint spars.

The clay is hauled by wagon from the railroad cars and dumped at different points in the yard, convenient to the machines to which they are to be furnished. Generally about 1,000 tons of these different clays are kept in storage. The clay is ground in Bonnot dry pans, and elevated to stationary screens on the fourth floor, from which they pass into the storage bins on the third floor. From these bins the various clays are measured in the proportions desired and delivered into a 12-ft. Bonnot pug mill on the second floor, passing from this to a vertical wadmiil on the ground floor. These wads of prepared clay are then carried by trucks to an adjacent building, where the tempered clay is stored. From this store house the material is delivered by barrow or elevators to men on different floors, engaged in pressing the clay into the different molds. Drying floors are to be found in each building, both live and exhaust steam being used. The time for drying of course caries with the size and shape of the pieces, but great care has to be taken in the drying, for in terra cotta work quality ranks before speed, and with the St. Louis Terra Cotta Co. quality is considered as all-important.

The dried products are then conveyed to the kilns. There arc five large muffle kilns with a capacity of about 40 tons each, 18 ft. in the clear, two experimental kilns, one fritt kiln and one short order kiln. Watersmoking and burning occupy about six days. The shipping facilities of the company are over the Missouri & Pacific and Frisco railroads. The company owns its own teams, but on special rush work is often obliged to hire additional teams. A large shipment has recently been made to the Union Electric Light & Power House, an important structure on the levee, at Biddle St. About 125 men are employed when the plant is in operation and work is carried on the year through. The plant also has a fine carpenter shop, a drafting and modeling laboratory, and the usual complement of glazing and blunging mills. R. F. Grady, the vice-president and manager of the company, was for seven years connected with the Evens & Howard Firebrick Co., and has had considerable experience in the manufacture of clay products. Mr. Grady is a broad-minded man, with an artistic temperament, with a keen eye for the beautiful and a genuine belief in the future development of the terra cotta industry. Numerous experiments are continually conducted by him, and a recent success of his is the production of a very fine egg-shell glaze which should prove to be a winner.

The products of the plant are terra cotta, jardinieres, pedestals, and many other interesting side lines. We illustrate here a cemetery wall which has just been completed to bound a cemetery reservation in Missouri. It is finished in a rich brown glaze and the pillar and wall effect form a very beautiful combination. The reader will also note an entrance gate effect of similar design to private grounds. The clayworkers who visited Dayton, O., on their way back from Cincinnati, after the N. B. Al. A. Convention, unanimously admired the fine terra cotta works on the Union railway station here. This was also supplied by St. Louis Terra Cotta Co. Mr. Grady will be pleased to welcome clayworkers visiting the World’s Fair, St. Louis, and will be sure to have something of interest to show them.