By Wolsey Garnet Worcester

Edward Orton, Jr., Collaborator and Editor

1910

General

The origin of roofing tile is shrouded in obscurity. It can, however, be traced back several centuries before Christ. Early in man’s career, he doubtless lived in such caves and natural shelters as are found in a mountainous country, but, as he migrated from place to place, it would happen that natural shelters could not always be found. The impulse and suggestion for him to construct temporary caves, or shelters of slabs and pieces of rock, would be a perfectly natural one and doubtless has recurred many times in various places and peoples in the development of the human race. These early homes were no doubt covered with some sort of thatch or stone roofing material; in mountainous countries flat stones of flaggings would naturally be tried. Experience unquestionably soon taught these early home builders the value of a sloped roof over a flat one, in shedding the rains.

According to Morse,1 the antiquity of the sloping roof is hinted at in the finding of cinerary vessels in the form of huts, and, consequently, known as hut-urns. These have been found in Italy, Saxony and other parts of southern Europe. It is believed they were made before the age of iron.

The sloping roof must have preceded the roofing tile by many centuries. At the outset, bark, straw, thatch, rough stones and similar substances were used until better devices were made, which finally culminated in roofing tile of terra-cotta. The oldest known type of clay roofing tiles is, by far, the most common form in use in the world to-day.

Most natural stones crumble, and metals oxidize or rust, but hard burned clay wares are nearly imperishable to the influences of decay. Thus it happens that terra-cotta roofing tiles are often the only surviving relics of a prehistoric structure. The enduring nature of these objects may ultimately enable us to trace the paths followed by the tile-making races in their various migrations.

While the actual beginnings of roofing tiles are not known, it is probable that their use was known very early in Asia Minor, and certainly very early in China. From the high skill of the potters and the great antiquity of the fictile art in China, and the use of artistic roofing tiles in that country in buildings erected some centuries ago, one might easily be led to believe that it was in China that the use of roofing tile originated.

Graeber, in his memoir “Terra-kotten am Gieson,” describes what he believes to be the earliest known terra-cotta roofing tile. These were found in the ruins of the Temple of Hera at Olympia, dating nearly a thousand years before Christ. This ancient tile consisted of two elements, a wide under piece (tegula) slightly curved, and a narrow, semi-cylindrical piece (imbrex) which was placed in an inverted position so as to cover the upturned edges of two adjacent tegulae. While the tiles from the Temple of Hera are probably as old as any authenticated instances elsewhere, it is not to be supposed that the Greeks sprang all at once from the thatched hut of the wild sheep-herder, up to the level indicated by this efficient system of tile roofing. It is known that the beginnings of their other arts, pottery making, metal working, jewelry, sculptures, etc., were imported from older civilizations in Asia Minor, or elsewhere, and that while the genius of the Greeks soon developed all of these arts to a plane never before known in the world, they cannot be credited with their first discovery.

Figure 1—Tiles from the Temple of Hera.

Among the substances used in the construction of early roofs, worked marble tiles, modeled after the terra-cotta tiles, were made some 650 years before Christ.

Throughout all parts of the old world can be found tiles or the fragments of them, proving to us that the use of tile has been universal there at one period or another.

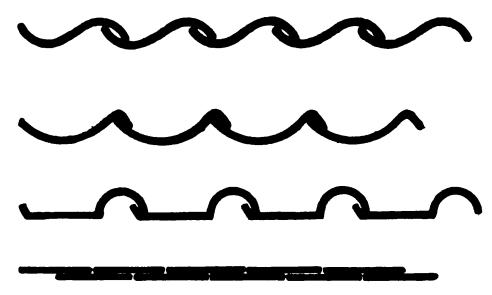

The outline drawings2 (Figure 2) represent in a general way the types and varieties of roofing tiles with their age and distribution.

Figure 2—Normal or Asiatic Tile Designs. From top to bottom:

The Orient, Ancient Greece and Italy.

China and Italy.

The Orient, Asia and Mediterranean Countries.

Greece, Italy (Ancient and Modern).

It should be understood that colonies, past and present, usually adhere to the form of roofing tile in use in their parent countries. As an illustration,3 flat tile made in Montgomery County, Pennsylvania, about 1735, can be traced to the old German settlers. At Bethlehem, Pennsylvania, the Moravians were making tile as early as 1740.4 The pan tile discovered by Dr. C. C. Abbott5 on Burlington Island, in the Delaware River, on the site of a very old house, said to have been built in 1668 by Peter Jagon, points clearly to the Dutch settler as its author. In California and Mexico, the normal or half round tile used in the missions were made by the early Spanish conquerors.

Figure 2—Continued. Pan or Belgic Tile Designs.

Top: England and Scandinavia.

Two middle: Belgium, Holland, Scandinavia, Java and Japan.

Bottom: Modern, various countries.

The tiles found in the above described localities are believed to represent the first use of roofing tiles in this country. It is quite possible that some of the first tiles used were brought from home by the colonists from their respective countries.

Ohio

Taking up the history of roofing tile in Ohio, it has been found a problem of less magnitude to trace their development.

On a branch of the Cincinnati Northern Railway, some thirty miles to the northeast of Cincinnati, is found the quaint old village of Germantown, which the records seem to indicate as the site of the first roofing tile manufacture and use in Ohio.

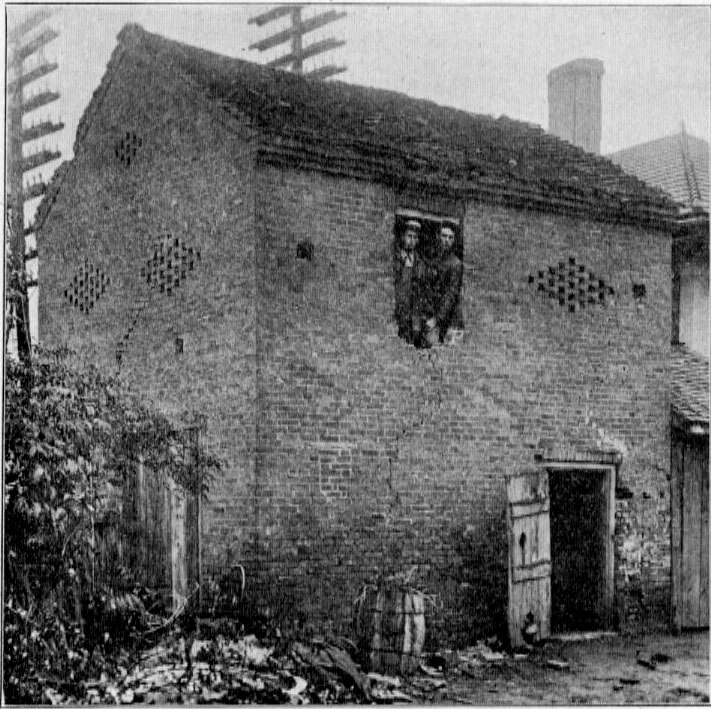

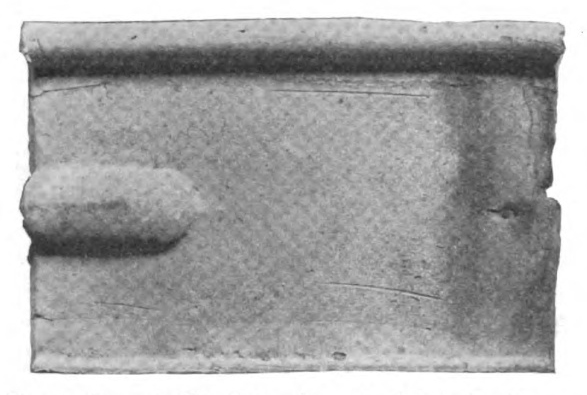

During the year of 1814,6 Mr. Philip Gunckel laid out the village, and named it after Germantown, a suburb of Philadelphia, which still retains that title. About this time a Mr. John Robinson cast his lot with the early settlers of the little town, and began the manufacture of brick from clay gathered in a nearby field. Wishing to build for himself a home that would outdo those of his pioneer neighbors, Mr. Robinson made clay roofing tiles in quantity sufficient to cover his home and stable. Figure 3 shows very clearly the form and outline of the tile made by Mr. Robinson. These tiles were no doubt made from the same clay, and burned in the same kilns, as the brick which Mr. Robinson manufactured. The house has long since been destroyed, but the old stable withstood the ravages of time and storm until 1907. It was razed to make way for a fine library building. The photograph shown in Figure 4 was taken just before the work of destroying the old building was begun.

The view of the stable shows the roof in a dilapidated condition, not from the failure of the tiles or brick in the structure, but from the rotting of the wooden beams and rafters, so that they could no longer carry their load.

Figure 3—Robinson’s Tile, made at Germantown, Ohio, about 1814.

To the right in the picture stands a corner of the new library building, upon which can be seen roofing tiles of modern manufacture. A more striking contrast could scarcely have been found, the one tile showing the marks of time and the primitive methods of manufacture of a century ago, while the other presents a roof of the present day.

The Robinson tile at Germantown was probably a sporadic case only, and does not probably stand for the introduction of the industry, as we have no evidence that he manufactured tiles for other than his own needs.

Unquestionably, the next step in the production of roofing tile in Ohio was taken by the Zoarites, a German religious sect, who settled in Tuscarawas County about 1820, and built a town which they called Zoar. The manufacture of roofing tile by these people was upon a much larger scale than the early efforts of Mr. Robinson at Germantown, as practically all of their buildings were tiled. One only has to look upon the many old roofs that can still be seen standing today at Zoar, to recognize that the use of roofing tiles was not new to the people of Zoar. They came from a country where tiles had been used for centuries before they sailed away to build their Utopia in the wilderness, where they could be free to follow their own beliefs. The Zoar community has disbanded after communal existence of about eighty years, but their honest workmanship and care have left buildings and roofs which will last for many decades to come.

Figure 4—Building covered about 1814 with Tiles made at Germantown, Ohio.

These Zoar tiles are shingle tiles of the pattern known as the “Beaver Tail,” the outline and style of which can be traced back to their native town, Wurtemburg. The tiles were all hand made; the clay was dug in the nearby fields, hauled to the tile yards by oxen, dumped into soak-pits, where water was added and the clay allowed to stand till soft. After soaking for a day and night, men tramped the clay with their bare feet until it was properly kneaded or pugged. It was then covered over with straw, weighted with rails or boards, thus keeping the clay plastic until needed by the molders. It was then spaded out, and carried by hand to the small workbenches of the molders. Wooden molds were used, which were previously wet and then sprinkled with sand. The molder first took up a lump of clay, which he rolled into a long tapered roll similar in shape to a loaf of rye bread. This roll of clay was then thrown or slammed forcibly into the center of the mold, and the molder, using his forearm and hand, would hammer or manipulate the clay until it completely filled the mold. The excess clay was then scraped off with a straight edged stick. Ordinarily the tile would have been considered complete at this point, but by observing the tiles shown in the illustrations, it can be seen that their faces have been grooved with gutters, or lines running lengthwise of the tile. These grooves were produced by the fingers of the workmen, each finishing his tile with lines that seemed most appropriate to him.

Figure 5—Roofing Tiles made by the Zoar Community.

A two-fold purpose was filled by these grooves: first, they broke the monotony of the otherwise plain tile, and secondly, they furnished a means of keeping the rain water away from the lateral joints.

The tiles were carried from the molding benches by boys, to drying racks or floors, where they were emptied out from the molds and left to dry. The mold was carried back to the work bench, where it was first dipped in water and then sprinkled with sand, in readiness for another operation.

The burning was carried on in up-draft kilns similar to the up-draft clamp kilns used by manufacturers of soft mud bricks at the present time.

Tile manufacture was carried on by these quaint people until about 1852, when it was discontinued. As at Germantown, the tiles made at Zoar were not designed for commercial purposes, but merely to be used on the mills, store houses, shops, houses and barns of the Zoar community, amounting in all to a considerable number of structures.

The next step in the evolution of the manufacture of roofing tile in Ohio and probably the earliest establishment of the industry on a commercial basis in the United States, came during the year 1871, when Mr. J. B. Hughes of Terre Haute, Indiana, received letters patent on roofing tile of interlocking design, and at the same time on a machine to make such tiles.

Figure 6—Old Church at Zoar, Ohio.

Among the first to become interested in the Hughes tile, was John W. Conrade of Zanesville, Ohio, who during the year 1873 purchased the right to manufacture the Hughes tile. Mr. Conrade opened a small plant during the fall of the same year and carried on the manufacture of tile during the following winter. No roofs were covered, however, until the spring of 1874, when the residence of Mr. A. H. Watts in Zanesville was constructed with this tile. The Conrade factory did not continue long in operation.

Closely following the starting of the Conrade plant at Zanesville, Mr. Edwin Bennett at Baltimore, Maryland, embarked in roofing tile manufacture. In the beginning, the Bennett plant was also operated under the Hughes patents. Mr. Bennett was without doubt the second man in this country to take up the manufacture of roofing tile on a commercial scale. His plant was opened in 1876 and was in continuous operation up until the summer of 1908, when, owing to the death of Mr. Bennett, operations were stopped and it has since been dismantled.

Arriving in this country in 1841 from Woodville, Derbyshire, England, Mr. Bennett7 joined his brother James Bennett at East Liverpool, Ohio, in a small pottery works which had been started in 1839 at that point, and which was undoubtedly the first pottery to be built at East Liverpool, and the foundation of the enormous industry which has developed there.

Figure 7—Conrade Tile Taken from the Watts Residence, Zanesville, Ohio.

During 1846 Mr. Edwin Bennett severed his connection at East Liverpool, and moved to Baltimore, where he founded a whiteware pottery which is still in successful operation to-day. But, becoming interested in roofing tile in 1876, he embarked in the business in a small way. His entrance into this field was interesting, in that it marked a line of growth very unusual at that time and still so. The English potter as a rule has great pride in his craft, and a proportionate distaste for the other branches of clay manufacture, especially bricks and tiles, which he regards as on an entirely different plane from his own. But Mr. Bennett’s vision was prophetic, in that he saw the ultimate importance of roofing tiles and the certainty of their use in enormous quantities, and he decided to apply his knowledge of clay manufacture to this new line. Unfortunately his efforts were largely premature, as the markets had not been at all educated to the use of tiles.

A year or so later, in 1877-78, Mr. Harris B. Camp at Cuyahoga Falls, Ohio, entered upon rooting tile manufacture.

Mr. Camp had a most interesting personality. He owned a factory for the manufacture of sewer pipe and hollow goods, and also a machine shop of considerable size, where he did a custom trade as well as building and repairing his own clay machinery. He was an inventive genius of a high order, but of the rare type that makes his ideas pay. He experimented continually, seldom doing the same thing twice alike, even when successful. He became very wealthy before his death. Mr. Camp’s efforts in the roofing tile field were directed to the manufacture of the well known diamond shaped pattern, invented by Courtois in France prior to 1856. He only continued a short time in this branch of clay manufacture, when he sold his interests to Mr. J. C. Ewart of Akron, Ohio.

Mr. Ewart took up the work with much faith and energy, and has unquestionably done as much or more than any other man to promote the use of roofing tile in the United States. The plant which he built at Akron in the late seventies was strengthened step by step and for many years held the record of being the largest and practically the only successful plant of its kind in this country, as the Bennett plant did not at any time assume large proportions, and was not largely known in the trade. Mr. Ewart’s success in his business was due entirely to his energy and application. He accomplished what he did almost entirely by his own efforts, relying very little on exchanging ideas with other clay workers. He solved his own problems in his own way, and did this at a time before clay working had begun its modern expansion and control along chemical and mechanical lines. His methods, and especially his exclusiveness, did not enable him to retain the control of the business which he had by great labor secured. Opposition began to develop, and ultimately his position became difficult. He finally withdrew from the business a few years ago, the plant being taken over by the present firm, The Akron Vitrified Roofing Tile Co.

It was not until a number of years after the starting of the Akron plant, that the roofing tile business was taken up by other manufacturers throughout the state. Among them was The Repp Roofing Tile Co., New Philadelphia, Ohio, about 1893; The Barnard Tile Co., Bellaire, Ohio in 1893; Zanesville Roofing Tile Co., at Zanesville, Ohio, in 1895; another one at Ottawa, Ohio, in 1900. None of the above plants operated to exceed three or four years at the longest, and none were successful in founding successful industries. About the same time, i. e., in 1895, a plant known as the Cincinnati Roofing Tile and Terra Cotta Co. was started at Winton Place, near Cincinnati, by Mr. Jacob Freund, inspired, as many of our German citizens are, with a true love and appreciation of a good tile roof.

Starting in a very modest way, this plant was built up step by step by its founder and associates. The problems of manufacture here were studied independently and met in their own way, as in the Akron plant, and while the product was of different shape and design, the business became slowly successful. It was founded on solid experience at every step of the way, and succeeded where the other plants of its own age failed, chiefly because it was not a copy of any other plant and because it evolved its own methods.

In 1902 a roofing tile plant at New Lexington, Ohio, was erected by a company of which Mr. A. W. Brown was President. This plant, at the time of its building, was designed upon broad lines, with ample provisions for enlargement, and, in its short career of eight years, has developed into the next to the largest, if not the largest, roofing tile plant in the United States.

Following the New Lexington plant was one at Lima, Ohio, The National Roofing Tile Co., built by Mr. A. B. Klay, a native of Switzerland. Having been born and reared in a country where tile roofs have been the main reliance for centuries, it was only natural that Mr. Klay should see the great possibilities for roofing tile in this country.

Since gathering the field notes for this report, during the summer of 1908, a company has been formed at Canton, to build a plant at Sparta, Ohio, to manufacture dry-pressed roofing tile.

Other States

Considering the establishment of plants outside of Ohio, the Mitchell Clay Co.8 during the year 1866 undertook the manufacture of roofing tile at St. Louis. They were, however, in advance of the times and after a period of about five years they discontinued the manufacture of this line of goods.

Other attempts were made at several points throughout the country, none of which met with success until the starting of the Celadon Terra Cotta Co., of Alfred, New York, built in 1888 by Mr. Geo. Babcock. This plant was one of the pioneers, and has been in continuous operation from the time of its building. At present it is one of the plants owned by the Ludowici Celadon Co., of Chicago, Ill.9 During 1890 a plant for the manufacture of roofing tile was built at Ottawa, Ill., and known as the Chicago Terra Cotta Roofing and Siding Tile Co. It was operated by various owners for about twelve years and then was dismantled.

About 1893 the Ludowici Roofing Tile Company was formed in this country and built a plant at Chicago Heights, Illinois. This plant has grown steadily from the start until today it ranks among the largest.

The next plants of importance were the Standard Roofing Tile Company, St. Louis, built in 1895, and the Ohio Valley Clay Shingle Company, now the Huntington Roofing Tile Company of Huntington, West Virginia, built in 1899. During the following year, 1900, the Ludowici Roofing Tile Company built a plant at Liberty City (now Ludowici) Georgia.

It was not until three years later that other plants were built. During the year of 1903 there were three plants built, The United States Roofing Tile Company, Parkersburgh, West Virginia, The Mound City Roofing Tile Company, St. Louis, Missouri, and the Western Roofing Tile Company, Coffeyville, Kansas. The next year or during 1904, The Murray Roofing Tile Company was built at Cloverport, Kentucky; following this company was the building of the Detroit Roofing Tile Company in 1906.

The latest company to enter the roofing tile field is the New York Roofing Tile Company at Saugerties, New York.

Other companies that are manufacturing or have manufactured roofing tiles, either alone or in connection with other clay products, are: The Alfred Clay Company, Alfred, New York; Burns and Russell, Baltimore, Maryland; Golden Press Brick Company, Golden, Colorado, Los Angeles Pressed Brick Company, Los Angeles, California; Gladding, McBean & Co., Lincoln, California; The Steiger Terra Cotta & Pottery Co., South San Francisco, California; N. Clark & Sons Co., Alameda, California; The Carnegie Brick & Pottery Co., Tesla, California; The Clay Shingle Company, Montezuma, Indiana; Spillman Brick Company, Spillman, West Virginia, and probably a number of others.

Status of Manufacture Outside of United States

Roofing tiles are now manufactured in all parts of the world occupied by civilized races. In the far East we find well established industries in China, Japan, Java, India and the islands of the Asiatic coast. The manufacture of tiles in these countries is possibly not as great at the present time, as it has been in the past, owing to the frequent relaying of the excellent tiles, made years ago by their ancestors, on modern structures.

It can be said of the Chinese, that they excel all other races in the world in their skill in the use of roofing tile. Estates and residences are generally bounded by high brick walls, crested with tiles, and even the most common country homes have at least a tile-covered gateway, while temples, shops, and all buildings of the better class are tile covered as a matter of course. Moreover, China, Korea and Japan have all treated the roofing tile in an artistic way approached by no other countries, excepting Greece and Italy.

Passing on to Persia, Egypt and the countries bordering on the south and east coasts of the Mediterranean Sea, we find that many tiles are still used, and that they retain for the most part the old normal pattern.

In Italy, Switzerland, Spain, Asia Minor, Austria, Norway, Sweden, Belgium and Holland are many thousands of tiled roofs, but these countries are not properly called large producers of roofing tiles. They do not manufacture many tiles in excess of those needed for domestic use. On the other hand, Germany, France and England are all large manufacturers of tiles. They annually produce many squares for export purposes to South Africa, South and Central America, and the West India Islands. Some few tiles are manufactured in these latter countries, but their supply is for the most part imported. At Maracaibo, Venezuela, there are two plants making tiles: The Eastern Brick and Roofing Tile Co., which has been in operation for the last fifteen years, producing roofing tile by means of a French hand-power press, and the Western Brick & Tile Co., using a similar equipment. The combined output of these two plants is naturally small, and hence the bulk of the demand has to be met by importations.

At Montevideo, Uruguay, Mr. John W. O’Hara, U. S. Consul, reports that the majority of roofs in that country are flat, like floors, being paved or covered with flat tiles like the English “quarries,” locally known as “baldosas.” Many thousands of these are annually used, and he reports that in a single six months 2,537,000 were imported, largely from England.

A vast amount of business in these southern countries is yearly lost to the United States, due partly to the scarcity of roofing tile plants in this country, more especially on our southern, southeastern and southwestern sea board. At present we have only one plant in this vast territory, viz., at Ludowici, Georgia. This situation is also undoubtedly due in considerable part to our insufficient and irregular lines of communication with these countries. American ships are rare in those waters and the bulk of American exports to them go in foreign bottoms. Another cause is the lack of knowledge of our American producers as to what is wanted by these southern neighbors, and generally a tendency to impatience with their demands for special shapes and styles. The English and Germans have secured the trade, by finding out what the customs of the country require, and supplying it, while Americans have in some instances adopted a “take it or leave it” policy which is very unsuccessful in securing trade.

Some tiles are produced in Cuba and Mexico, but only in the slow and primitive manner brought in by the Spaniards three hundred years ago.

In Australia many tile plants have been put into operation by the English, German and French settlers.

Status of Manufacture in the United States

While the first manufacturing of roofing tiles in this country has been shown in the preceding pages not to be of recent date, it is nevertheless a comparatively new industry here. We have been slow in taking up the use of roofing tiles for several reasons which are discussed in detail a little later. At present, however, American ingenuity in this field, as in many others, has triumphed over time and tradition. Although slow to enter this field, our progress since entering it has been rapid, and American tiles today have many points of excellence, and some of superiority. From the crude presses brought into this country from Germany, England and France, our inventors have developed new roofing tile machinery that leads the world in simplicity, strength and output. Many improvements in the materials of which dies are made, and also in the construction of dies, have been made in the past few years, until now the time honored plaster die is to be found in but few roofing tile plants. The chief objection to plaster dies has been that they must be renewed daily, owing to the rapid rate at which the soft plaster surface wears away, leaving the tile made upon them with a very rough and uneven exterior, which catches dust and dirt, and soon presents anything but an attractive appearance. To overcome these objections, our manufacturers have employed dies made of such materials as cast iron, steel, brass, gun-metal, aluminium, and various alloys, all of which are being used with more or less success.

Figure 8—Map of the United States, Showing Distribution of the Roofing Tile Plants.

In the past thirty years, the capacity of the roofing tile plants in this country has grown from the insignificant sum of from twenty-five to fifty squares per day, which is about the output of a single average plant, up to nine hundred or a thousand squares per day, if worked full time. In other words, the output has been increased from that of sufficient tile per day to cover a single medium sized building, to a number that would cover, roughly speaking, about twenty buildings of the same size.

It will be seen from Figure 8 that with two exceptions the plants are centrally located. It will also be observed that Ohio ranks first in the number of plants, with West Virginia and New York as second.

Table No. 1.

| State | No. Active Plants | No. Building | No. Idle |

|---|---|---|---|

| Ohio | 4 | 1 | 0 |

| West Virginia | 2 | 0 | 0 |

| New York | 2* | 1 | 0 |

| Illinois | 1 | 0 | 0 |

| Michigan | 1 | 0 | 0 |

| Kentucky | 1 | 0 | 0 |

| Missouri | 1 | 0 | 1 |

| Kansas | 1 | 0 | 0 |

| Georgia | 1 | 0 | 0 |

| California | 4** | 0 | 0 |

*One of these is in connection with dry press brick.

**All made in factories whose product covers a wide variety of clay wares. Roofing tile is not an important item in any of these plants, though made in all.

Ohio, at the present time, as always in the past, leads all other states in the production of roofing tile, as already shown. The first commercial roofing tile plant in this country was developed in Ohio, at Zanesville in 1873, and from the opening of the Zanesville plant, Ohio has, at no time, been without roofing tile industry, somewhere in her borders. Ohio manufacturers have generally kept abreast of the times, and have fought many of the hard battles necessarily encountered in the introduction of a new industry. In the face of the cheaper natural roofing materials, and also of the failure of some of the poorly made tiles and poorly laid tile roofs of early days, Ohio manufacturers have continually sought to produce more and better tiles, and to prove to the most exacting architect or builder that there is no other roofing material as nearly perfect as a well designed and well made roofing tile.

Approximately one-third of all the roofing tiles made in the United States are now produced in Ohio, and with the completion of the plant now in process of construction, the proportion will probably be raised somewhat higher.

Slow Development of the Industry in America

Why have not tiles been used more extensively in the United States in view of their very extensive use abroad? There have been several conditions in the past which have greatly impeded the development of the industry. Some of these conditions still exist in some parts of the country. A discussion of these conditions will furnish an answer to the above question.

Firstly.

The competition of the wooden roof should be considered. The country is relatively new, and most of it originally abounded with magnificent forests of timber, suited for use as shingles. Cleared land was, and in some sections still is, at a premium, and any use to which the primeval forests could be put was gladly welcomed. While this surplusage of timber has now passed away forever in the east and central portions of the country, which are not beginning to feel the pinch of scarcity and to realize the awful wastefulness of the past, in some sections of the Northwest it is still possible to see enormous quantities of wood ruthlessly burnt, in order to get rid of it. Thus for many years the use of other roofs than wooden slabs or shingles was very limited, owing to their cheapness and availability. As time passed and neighborhoods became towns, and towns cities, disastrous fires have occurred which have pointed out the importance of some more fire-proof roofing material, since the shingle-roofed house has formed a vulnerable point of attack in every large conflagration in this country, and in thousands of small fires. Thus the wooden roof, while still largely used, especially in the newer sections of the country, is doomed to a more and more rapid extinction, under the joint influences of increasing scantiness of wood supply, short life of wooden roofs under favorable conditions, and their constant danger of destruction by fire.

Secondly.

The competition of slate or natural stone. The conditions described as to the wooden roof have generally been first met by resort to slate, a natural stone of highly fissile character, capable of being readily sawed up into blocks of proper size, and split into very thin slabs of even thickness, which will stand further shaping and punching at the point of use.

The United States is fortunate in having a large natural endowment of slate, in widely distributed localities, and these quarries have been and will always be a source of much wealth to their communities. But slate is not free from faults, though it has many advantages which will always entitle it to an important place among roofing materials. It is cheap, easily applied, fireproof, and resistant to weather if of good quality. On the other hand, it is heavy, it is not resistant to weather if it contains soluble minerals, or easily oxidizable minerals like pyrites, or if it is not hard enough, i. e., too shaly. Also it is not very resistant to blows or strains, is not easy to repair when once laid in place, losses in shipping and application are rather high, and it makes a very plain, unornamental and uninteresting roof. The last reason is the most important of these, and were it not for this, slate would make the introduction of roofing tile a very slow and unprofitable venture. But slate only works in planes. It cannot be easily adjusted to curved surfaces, it possesses no relief, and makes a textureless roof and therefore one devoid of character, and its range of colors is limited to a small variety of blues, greens, browns and dull reds.

Thirdly.

The use of metal roofs, such as sheet iron, plain or coated with zinc or tin, and the use of corrugated or crimped or pressed iron plates has found a large field. The use of other sheet metals, such as pure zinc, copper or tin, is possible in some few cases, but in general is precluded by cost. The use of sheet iron in its various forms has the advantage of cheapness, non-combustibility, exceeding lightness, ready adaptability to any shaped structure, exceedingly rapid application, and easy repair, and easy preservation by paint applications. On the other hand, it is very short lived unless thoroughly protected by paint or other applications at frequent intervals, and is thoroughly uninteresting in its appearance when finished, unless the pressing has gone to the extent of closely imitating roofing tile, in order to get the relief and texture. In this case, it is more costly than a metal roof ought to be, and has all the faults of any material which merely copies another.

The field of the sheet metal roof will therefore be likely to grow less rather than greater, and it will probably be confined more to factories, barns and low class sheds, and less to buildings with pretension to architectural merit.

Fourthly.

Composition roofs, made of sheets of artificial fabrics like paper, felt, asbestos, cloth, etc., water proofed with tar, asphalt, paint, and numerous patented and secret preparations, and covered with surface coatings of sand or gravel, are an important mode of covering cheap or temporary structures. Such roofs are largely confined to factories, flat roofed stores and store houses, and seldom applied to dwellings or important structures of any kind. However, they have the merit of cheapness, of water proof character to a very high degree even at low angles of pitch, of easy application and easy repair or removal. They lose their elasticity and crack and leak, if the filling material is allowed to dry out too long without renewal. They often are resistant to fire from the outside, though nearly always highly inflammable from within. The tar or asphalt roofs cannot be used on heavy slopes on account of drainage of the fluid during the summer heat. They are limited to strictly utilitarian purposes, having no pretensions to beauty under any circumstances.

Fifthly.

Cement roofing is a new factor in the market, which may be applied in two ways: 1st, as tiles made separately and subsequently applied and fastened in place, or 2nd, in sheets of reinforced concrete. Of the former, a comparison with clay roofing tiles will be made later. Of the latter, the strong points are its rigidity, its fire proof nature, its permanence when well made. Against it, lie the probability of bad workmanship (or the difficulty of securing good workmanship on which its duration and strength directly rest). Cement products in general are all open to this difficulty, that it is not easy to tell whether they are well made or not from their appearance, i. e., scanting in material or workmanship is exceedingly difficult to detect and where so much dependence must be placed on good faith, frequent abuses are always likely. Also, this style of roof is very heavy, and requires massive construction. Light or thin slabs are not satisfactory at all, as they crack if bent much or struck smartly.

Evidently, in competition with these five classes of roofing materials, most of them well entrenched in trade practice, roofing tiles have had to demonstrate their worth. Tile roofs have been unusual, therefore not easily obtained and often causing long delays in completion of a building. They have been heavy, requiring strong construction and thus more costly. They have been poorly laid, by workmen unskilled in their use and oftentimes actually hostile to the new roof and glad to see it become unpopular on account of leaks or early repairs. They have been inherently more costly. But in spite of all those handicaps, and others not mentioned, the use of tile has increased more and mere rapidly with each year. Its advantage in the hands of a skillful user, in the beauty of form, of surface texture, and of color, and its entire satisfactoriness when properly designed, made and laid, so far as weight and water-tight qualities are concerned, its uninflammable character and its actual resistance to the influence of exterior fire or water or both, its durability when properly designed and laid, all these and other advantages have been recognized by architects so thoroughly that now the great majority of large institutional buildings, fine residences, and others where architectural considerations have weight, use the tile roof. It has not yet invaded the field of the cheap roof, and it is by no means certain, under American conditions as to both labor and materials, that it ever will attain the wide usage which characterizes its use in Europe and in the Orient.

Handicaps

Some of the handicaps by which the use of roofing tiles has been limited in the past will, however, undoubtedly be removed as time goes on. In the first place, the design of a roofing tile, which can meet the exacting conditions of modern use, is becoming a less varied and more definite thing. Many fanciful, impractical and clumsy tiles have been “invented” or designed by various enthusiasts and their introduction has tended to hurt the cause and delay the use of the designs which are practical. Many of these theories have had to be tried out and lived down afterwards. Many of the leaky roofs and most of the slowness of tile roof construction has been due to poor design, part of it to poor workmanship. Secondly.—The weight of the early tile roof was excessive. Better machinery, better driers, better kilns, and more knowledge and experience on the part of the makers have overcome this objection in large part, and tile roofs are now furnished in which the weight consideration is no longer of much importance. Thirdly, the multiplication of plants will remove one of the biggest obstacles to the growth of the industry. With the avoidance of the excessive freight costs, and with the elimination of the delays caused by long shipments and frequently by congested factory conditions, there will come a great expansion in the use of tiles, not only from an economical standpoint, but from the side of artistic beauty, attainable by no other roofing material. With tile it is possible to get an everlasting roof in any pattern and of any desired color. The color is contained in a vitrified body, hence it is non-fading, which is more than can be said of any other coloring compound used for any kind of a roof.

Cement Tiles

Within the last few years many patents have been taken out for cement roofing tile. Plants have been started here and there over the country from time to time, the greater majority of which have been failures. Several plants have started in Ohio, namely at Columbus, Lancaster and other points. Detroit, Michigan, also at one time had a cement tile plant. The trouble has been to produce a tile which is not too porous, and which would not crack from expansion and contraction on the roof. To overcome this, they have necessarily been made very heavy. A second strong objection has been the inability to get permanent colors. Although minerals and mineral oxides are used as colors, in the course of a single year they have been known to fade, presenting anything but an attractive appearance. Numerous roofs in Detroit covered with colored cement tiles are examples of this.

Asbestos Tiles

A material lately come upon the market is a cement asbestos shingle or tile. This material is proving far better than the regular cement tile, on account of its extreme lightness and a certain amount of elasticity. The same objection can be made against this tile as against the regular cement tile, viz., it will prove very unsatisfactory when the question of color is considered. Furthermore, they have been known to warp badly, when exposed to the sun. To overcome this trouble a copper clamp or fastener has been devised and is being used on the later roofs of this material.

There undoubtedly will be a field for this material on large roofs of cheap construction, where extreme lightness is necessary, but for strictly first class and artistic work where something other than a flat or corrugated shingle is wanted, clay roofing tile will not likely be displaced.

Scanty Distribution of Roofing Tile Plants

This question is perhaps the most important in connection with the promotion of the business. With at present only about one plant to three and one-half states, it is not remarkable that tiles are not more widely used. In many sections of the country a tile roof has never been seen. At the present time, not a single plant exists in our entire eastern coast region. In the entire South, only one plant can be mentioned, while the Southwest and West has not one single plant producing roofing tile as its sole output. In three or four plants in California, some few tiles are made in connection with other ware, but tiles form a minor part of the total output. When there are tile plants scattered through all the sections of our country, then we will begin to see the use of tile as a standard commodity, as bricks are used to-day. Nearly every town has its common brick yard, and nearly every state has one or more face or front brick plants, producing a high grade article, whose value will justify a freight rate to the large cities.

Thus should it be with roofing tiles. There is no present or future chance of shipping cheap tiles for covering barns and sheds. These should be made locally and carried in stock by dealers after the manner of the European countries. But the better class of tiles, such as Spanish, glazed and slipped, should be made by larger plants where proper material can be had, and shipped reasonable distances to their markets, as face brick and terra cotta are.

These conditions actually exist now, in respect to the character of plants that are now doing business. There are in practically every case well constructed and carefully operated factories, which reach their markets by long distance shipments almost exclusively. But in the future, with three or four such plants in each of the well settled states to care for the finer trade, and with cheap tiles made in local yards for the cheaper trade, the industry will begin to compare with the development which it has reached in most other part of the world.

From time to time statements are made in the clay trade journals by various writers, that the present day brick manufacturers should take up the manufacture of roofing tiles in connection with their present business. Such advice is extremely ill considered. The manufacture of roofing tiles is a business by itself and should receive the undivided attention of those in charge. The methods of drying, setting and burning are widely different from those of brick manufacture and attempts in the past to burn brick and tiles in the same kiln have proven in a large measure a failure. In addition, the practice is not economical. The tiles can be burned in a much shorter time than the brick, hence it is a waste of time and fuel to hold the tiles under fire, waiting for the brick to receive the necessary heat treatment.

There is no more reason for associating the manufacture of roofing tile with that of brick and drain tile, than for associating the manufacture of terra cotta with the same articles, or the manufacture of crude stoneware with fine porcelain.

Endnotes

- Morse, E. S. “On the Older Forms of Terra-Cotta Roofing Tiles,” Amer. Arch. and Building News [1892] vol. 35, p. 197, vol. 36, pp. 5, 24, 52. This article has been freely used in various parts of this chapter, for which due acknowledgement is hereby rendered.

- After Morse, On the Older Forms of Terra Cotta Roofing Tile, Amer. Archt. and Building News, (1892), Vol. 35, p. 198.

- Barber, E. A. Pottery and Porcelain of the United States, p. 51.

- loc. cit.

- loc. cit.

- Howe’s History of Ohio., Vol. 2, p. 301.

- Barber, op. cit., p. 192.

- Wheeler, H. A., Mo. Geol. Surv., Vol. XI, p. 436.

- Destroyed by fire in fall of 1909.

Source: Reformatted chapter from The Manufacture of Roofing Tiles (Geological Survey of Ohio. Fourth Series, Bulletin 11).